Infrastructure

We are very particular about the products made and the way they are made. We ensure not only the highest quality standards but also the working conditions under which they are made. The welfare of our workforce and care for Nature during our manufacturing process in particular is a part of our vision.

LEGAL REGULATIONS

We strictly follow the minimum legal regulations for labour, law, health & safety compliance, products safety and comply with the environmental standards.

HUMAN RIGHTS

We adhere to and respect the tenets of human rights. Committed to upholding ethical practices and following the regulations and legislation.

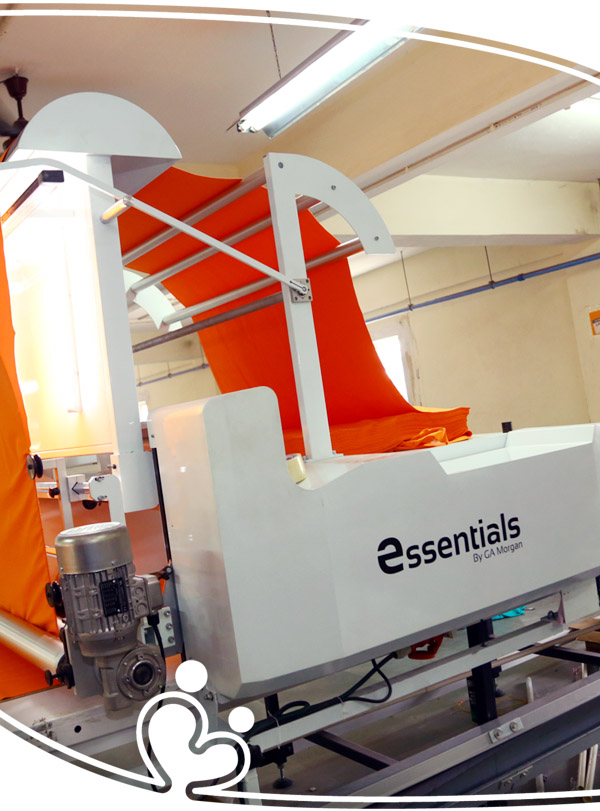

We have a highly equipped state-of-the-art manufacturing facility located in Eastern India with a one lakh sq. ft. operating area.

The production capacity is around 17 million pieces annually. More than 800 ultra-modern sewing machines with automatic cutting and spreading facilities are mobilized.